Substation Maintenance

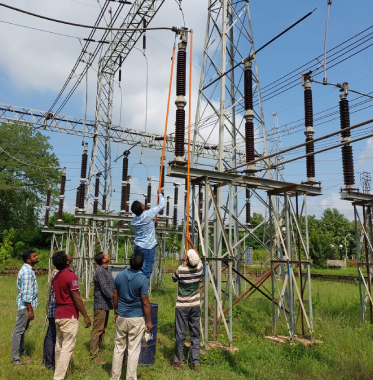

Substation Maintenance

At Sriva Live Line Services, we provide comprehensive Substation Maintenance Services designed to ensure continuous, safe, and efficient operation of electrical substations. Our preventive and corrective maintenance programs reduce downtime, extend equipment life, and maintain system reliability.

Scope of Work

- Visual inspection and testing of electrical components

- Tightening of connections and terminal checks

- Transformer oil testing and filtration

- Bus bar and isolator maintenance

- Thermal scanning and fault detection

Why Choose Us

- Experienced, certified maintenance engineers

- Use of advanced diagnostic tools

- NABL/NABL-compliant testing and calibration

- Safety-focused and timely execution

Applications: Power distribution utilities, industrial plants, renewable energy projects, and commercial substations.

Keywords: Substation Maintenance, Electrical Substation Services, Preventive Maintenance, Transformer Testing, Power Distribution Maintenance, Substation Service Provider

Insulator Replacement

Insulators are critical for maintaining the reliability of power transmission lines. We offer professional insulator replacement services to prevent leakage current, flashovers, and breakdowns due to aging or environmental factors.

Service Features

- Replacement of porcelain, composite, or glass insulators

- Live-line and shutdown-based replacement

- Hot stick and bare-hand methods for energized lines

- Testing and verification of insulation strength

Benefits

- Improved transmission reliability

- Reduced line losses and outages

- Compliance with electrical safety standards

Insulator Replacement Service, Transmission Line Maintenance, Porcelain Insulator Replacement, Live Line Insulator Change, Power Line Repair.

Providing Jumpers

We provide jumper installation services for substations and transmission lines to ensure efficient electrical connectivity between conductors and equipment. Our expert team uses high-quality materials and safe work practices for both energized and de-energized systems.

Service Highlights

- Installation of copper/aluminum jumpers

- Jumper connection for transformers, isolators, and busbars

- Live-line jumper provision under controlled conditions

- Voltage-specific and load-tested configurations

Keywords: Providing Jumpers, Jumper Installation, Electrical Jumper Services, Substation Jumper Connection, Power Line Jumper Work

Replacement of Jumpers

Over time, jumpers can deteriorate due to mechanical stress and thermal cycling. Our jumper replacement services help restore system reliability by using precision tools and certified technicians to safely replace existing connections.

Features

- Dismantling of old/damaged jumpers

- Replacement using crimped or bolted connectors

- Live-line or offline replacement options

- Quality assurance and continuity testing

Keywords: Replacement of Jumpers, Jumper Repair, Substation Jumper Replacement, Live Line Jumper Work, Electrical Maintenance

Providing Bypass Jumpers

Our bypass jumper services allow uninterrupted power flow during substation maintenance or fault rectification. These temporary connections are safely installed and removed using live-line techniques to prevent power disruption.

Key Advantages

- Enables maintenance without system shutdown

- Hot stick and bare-hand installation options

- Safe, temporary power rerouting

- Designed for different voltage levels

Keywords: Bypass Jumper Installation, Providing Bypass Jumpers, Live Line Maintenance, Substation Temporary Jumper, Power Continuity Services

Hot Spot Rectification

Hot spots in electrical systems can lead to severe failures if not addressed. Our Hot Spot Rectification Services identify and correct thermal faults using advanced thermography and live-line repair methods.

Process Includes

- Detection through thermal imaging

- Isolation and assessment of affected components

- Hot stick or bare-hand rectification techniques

- Re-testing and performance verification

Keywords: Substation Maintenance, Electrical Substation Services, Preventive Maintenance, Transformer Testing, Power Distribution Maintenance, Substation Service Provider

Hot Stick Method

The Hot Stick Method allows technicians to perform repairs on energized systems without interrupting power. Using insulated tools, maintenance is carried out from a safe distance ensuring maximum safety and reliability.

Applications: Jumper replacement, connector tightening, and insulator cleaning.

Keywords: Hot Stick Method, Live Line Maintenance, Insulated Tool Work, Hot Line Maintenance, Electrical Safety Tools

Bare Hand Method

The Bare Hand Method enables direct contact with energized conductors while maintaining the same electrical potential. This technique requires skilled technicians and specialized equipment to perform high-voltage maintenance safely and efficiently.

Applications: Transmission line repairs, jumper installation, and conductor maintenance.

Keywords: Bare Hand Method, Live Line Work, High Voltage Maintenance, Transmission Line Repair, Energized Line Services